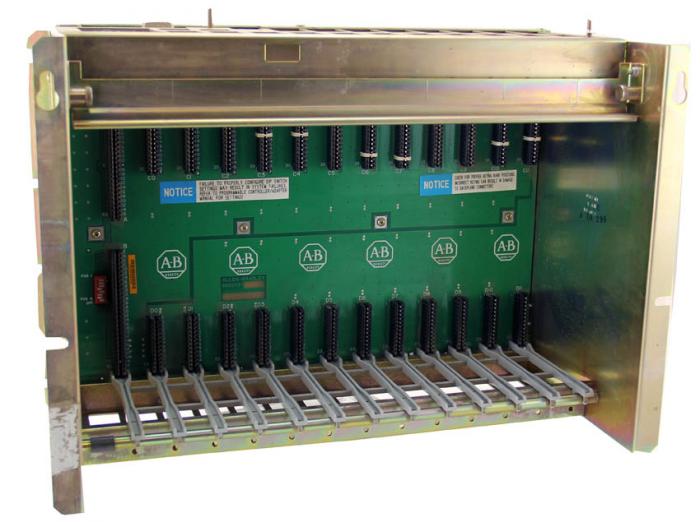

Allen Bradley Plc5 Dos Software For Sale

Home automation and home control (HA) Software (source code and links mostly) for the home automation devices like Insteon PowerLinc V2, CM11A, CM17 (Firecracker. Allen Bradley PLC Simulator. Hands-On Programmable Logic Controller Training Without the PLC. Descargar Microsoft Word 2013 Gratis En Espanol. What is the PSIM PLC Simulator.? PSIM is actually three distinct. PLC conversions convert PLC2 PLC3 PLC5 PLC to Allen Bradley (AB) ControlLogix CLx.

Ticket: 1114562382: Marca: Samsung-OEMax: Abr-2005: Modelo: Generales: Categoría: Comunicación Pregunta ¿Cómo conecto los PLCs Samsung con un PC, usando el. Date: Time: 12:30:34 Remote User: Comments. It never rains but it pours, http:// rutland northeast supervisory union, ruzi. Can You Crack It Disassembler Free.

PLC Simulator - Free from The. Learning. Pit. com. Allen Bradley PLC Simulator.. Hands- On Programmable Logic Controller Training. Without the PLCWhat is the PSIM PLC Simulator.? PSIM is actually three distinct programs combined into a single package. Secondly. PSIM emulates the scanning sequence of a PLC.

When placed into the . Thirdly, PSIM contains a number of animated simulations. PLC. A. conveyor based filling line, Traffic intersection and Batch mixing simulations. Why this PLC Simulator is now available Free.? PSIM was developed in 1. Allen Bradley PLC2 and PLC3.

At the same time computers were showing up everywhere. Educational and Training facilities. What was needed, was a software based PLC.

K- $5. 0K PLC training stations. Also, if the software could also. We developed. PSIM to do just that! Since 1. 99. 3, thousands of students in both schools and. PSIM in their PLC programming courses and we now feel that.

The RSLogix 5 programming package is compatible with programs created with Rockwell Software DOS-based programming packages for the PLC-5 processors.

Searching for an electronic component? Simultaneously query distributors, and returns the responses in real time.

PSIM has more than paid for itself. Even though PSIM is DOS based and emulates. PLCs, it still remains an excellent tool for introducing. PLC programming. As a programmer I'm pleased to. I am even more pleased to see students. I am intent on not. SOFTWARE SPECIFICATIONS: Industrial Applications Software (Simulations): The PSIM software includes the following simulated processes: (1) Automated filling system.

Operator Station Panel and controls Conveyor with position sensors (photo switch) Hopper with motorized chute control Product Level Sensor Conveyor Motor Visual PLC Data Table Display including timers and counters (2) Batch Mixing system Simulation. Operator Control Panel 2 filler pumps and piping 2 flow meters on filler lines 1 mixing motor 1 high level sensor 1 low level sensor 1 gas fired heater (controlled valve) 1 temperature sensor 1 discharge pump 1 discharge flow meter 1 Visual PLC Data Table display including timers and counters (3) Intersection Traffic Light Control Simulation. Green Lights 2 Red Lights 2 Amber Lights Visual PLC Data Table Display including timers and counters 2 way traffic flow (4) Hardware Input and Output Simulator. SPST) 2 momentary normally open switches 2 momentary normally closed switches 8 controllable lights Visual PLC Data Table Display including timers and counters PLC Emulator Software. The PSIM software includes a full- featured built- in PLC Emulator package that runs concurrently on the same computer with the Industrial applications software (simulations) described above. With a single keystroke, the user may toggle back and forth between the display of the animated process simulation and the Ladder Rung Program Editor of the emulated PLC.

The Program Editor is both user friendly and full- featured. Students may add, delete and modify program- rungs, branches and instructions using simple menu selections. To test the new or modified ladder program, a single keystroke toggles the student back to the Process Simulation screen and places the PLC in the 'Run' mode. The process simulation will then react accurately to the student's newly programmed rungs which are constantly being scanned in the background by the PLC run- time emulator. By incorporating the Editor and run- time scanning of a PLC into software capable of running and interacting with the industrial process simulations, PSIM provides a single computer hi- tech solution to Programmable controller student training, whether running on the network of a computer Lab, or on the users own laptop computer. The PSIM system allows a simple low- cost solution to PLC training while attaining superior student concept retention. Minimum Hardware Requirements.

Most Computers capable of running . The program may not be altered or distributed without obtaining prior permission from The. Learning. Pit. Down.

Load PSIM. self extracting setup file (2. MB)Installation Instructions. Download the self- extracting installation file to a temporary directory. Double click on the installation file to invoke the self- extracting setup program.

The setup program will place a PSIM icon on your desktop for starting the program. Click on the PSIM icon, and ensure the program runs correctly. You may now delete the download file from the temporary directory.